|

|

|

|

|

Ingenuity. Globally.

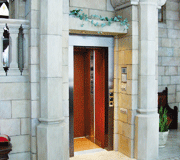

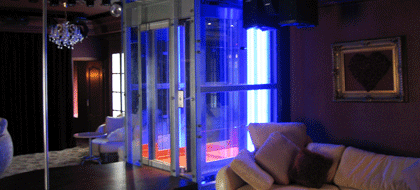

Our company was founded in 1989 around two core assets, its brand and its people. And, we believe in the principle idea of providing our clients, and or customers with flexible lift solutions.

Now, we’re one of the best known elevator brands in the world - present in more than 30 countries around the globe.

Since then, Axel has grown to become synonymous with exceptional quality and reliability with the use of precision technology together with exceptional manual craftsmanship. “Headquartered in Milan (Italy), the company is organized in three units: project management, lift and controller manufacturing, thus ensuring flexibility and an exceptional fast response time. It’s common for Axel to provide lifts within a few weeks from the receipt of order.

|

|

|

|

|

The Axel range is based on an OEM approach of the business: we deliver our products to lift companies and supply them with the technical support in order for them to service their customers.

Moreover, we are one of the few lift companies in the world who can design, develop and tailor-produce customize “Bespoke” solutions to meet the specific wishes, desires, dreams and needs of our clients, and or customers who are architects, developers and engineers who request exclusive individual lifts for their project(s).

At Axel, we remove chance from the equation by providing superb results consistently in our factory.

We are a results driven organization.

Therefore, quality control is taken very serious and this starts with our suppliers.

We only accept first class products onto our production line that have been approved by our in-house buying team.

And, each lift is tested from inception to completion by our experienced “Quality Control Managers” before delivered to customers.

Quality, functionality, engineering and design are all present in every lift manufactured by Axel down to the smallest details.

Come discover the company and the people behind the brand.

|

|

|

|

|

|

|

|

|

|

Quality & Environment Management Systems.

At Axel, all of our components and materials are carefully selected to ensure natural resources are used in a manner which does not adversely affect the environment. All supplier-side items used in our production methodology are selected using strict criteria. The elevator factory in Milan has lead by example with taken a leading role in reducing its energy consumption levels.

Since 1996, Axel has been at the forefront involving quality and quality assurance within its manufacturing processes by becoming one of the first lift companies to obtain ISO 9001 approval (and vision 2000). In addition, Axel gained approval in accordance to the Lift Directive (95/16/EC - schedule XIII). Therefore, all of our lifts comply with the European standard EN81. We also design, engineer and manufacture lifts according to Russian standards, Britain’s DDA and other standards upon request.

Each of our lifts are handled as a separate project and is fully documented and traceable through all stages of its elaboration for its Management of environmental issues.

|

|

|

|

|

|

|

|

|

|

|

Quality

Axel Axel was among the first lift companies to obtain ISO 9001 approval (and vision 2000) back in 1996.

In addition, Axel is approved in accordance with the Lift Directive (95/16/EC - schedule XIII).

All of our lifts comply with the European standard EN81.

We also supply the lifts according to Britain’s DDA and other standards on request.

Each lift is handled as a separate project and is fully traceable and documented through all the stages of its elaboration.

|

|

|

|

|

Innovative Production

Technology & Craftsmanship

Axel lifts are manufactured in our factory in Milan, Italy since 1989 using only the highest quality materials, fittings and production methods. Every processing stage is carefully carried out, checked and monitored. And, only after the completion of these stages is the product passed as acceptable to be used in the end product.

An ongoing certification of Quality Management system supports the company’s self-imposed philosophy of delivering only the best product to our clients, and or customers.

|

|

|

|

|

|

|

Long LifeSpan Tested

To ensure you can enjoy your elevator for many years to come all materials used are subjected to a number of endurance tests to make sure they will stand up to the rigors of every day life use.

As you would expect only the best results are acceptable.

|

|

|

|

|

|

Axel intelligent technology powers robotics

Axel has pioneered an intelligent technology that interacts with robotic systems, and allows the robots to assume full control of lift operations.

The inputs and outputs are communicated via CAN Bus Technology from the lift microprocessor to the I/O panel of the robot WAGO Panel connected to the host server. The robot controls door opening and closing operations, floor selections and any external lift landing call requests via a swipe card security system.

|

|

|

|

|

|

|

|

|

© Copyright 2011 - 2019 | Axel S.r.l.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|